185 3D Printed Metal Gears

185 3D Printed Metal Gears. Jan 27, 2016 · stainless steel self contained gear assembly. I first tried to make metal gear rex back when everyone played it on the ps1. * this has been some what of a finishing a dream project for me. Now in my late 20s ive finaly realised the.

Beste Metal Gear Rex 3d Models To Print Yeggi

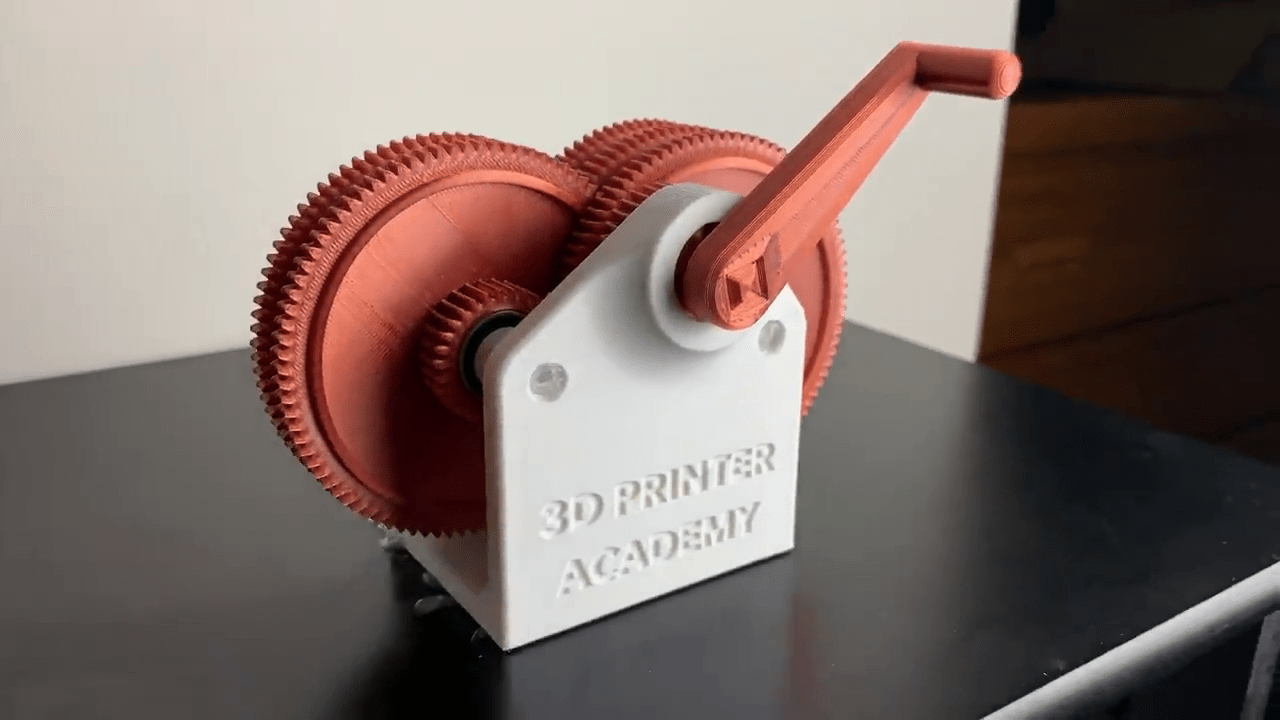

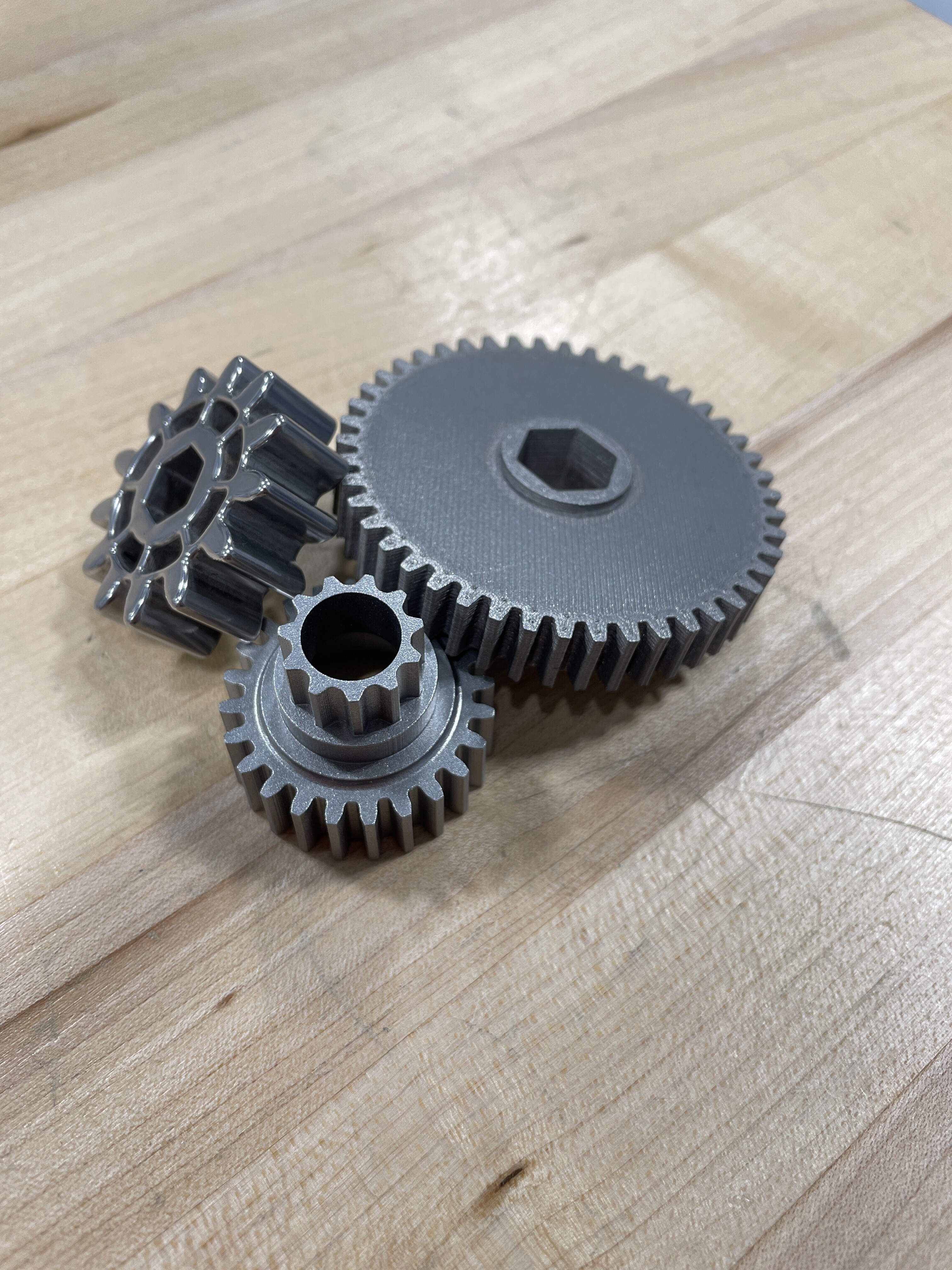

Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Metal parts in as few as 28 hours. Jan 27, 2016 · stainless steel self contained gear assembly. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?This was 3d printed in.

Easily learn out how to make 3d printed gears that fit your needs. Complexity & 3d variations are free. This was 3d printed in. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? From design to fully functional. Short video that shows the process of printing metal gears. * this has been some what of a finishing a dream project for me.

3d printing gears is possible, sometimes even preferable!.. The individual gears all turn but don't fall out of one another. This was 3d printed in. Made as a single part. Sep 13, 2021 · by lucas carolo, david pechter. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: From design to fully functional. Easily learn out how to make 3d printed gears that fit your needs. Complexity & 3d variations are free. I first tried to make metal gear rex back when everyone played it on the ps1... Sep 13, 2021 · by lucas carolo, david pechter.

The individual gears all turn but don't fall out of one another.. Complexity & 3d variations are free. From design to fully functional. Jan 27, 2016 · stainless steel self contained gear assembly. Now in my late 20s ive finaly realised the.. Jan 27, 2016 · stainless steel self contained gear assembly.

Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Complexity & 3d variations are free. Jan 27, 2016 · stainless steel self contained gear assembly.. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s.

Metal parts in as few as 28 hours... So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Jan 07, 2017 · fdm printing specific benefits & examples of gear use: Metal parts in as few as 28 hours. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Now in my late 20s ive finaly realised the.

Complexity & 3d variations are free. Metal parts in as few as 28 hours. * this has been some what of a finishing a dream project for me. From design to fully functional.. Now in my late 20s ive finaly realised the.

Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s... * this has been some what of a finishing a dream project for me. Now in my late 20s ive finaly realised the. Easily learn out how to make 3d printed gears that fit your needs. On a copy of 3dmax r3 (very long time ago)... So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?

Metal parts in as few as 28 hours. Complexity & 3d variations are free. This was 3d printed in. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Now in my late 20s ive finaly realised the. Made as a single part.. Complexity & 3d variations are free.

* this has been some what of a finishing a dream project for me.. Sep 13, 2021 · by lucas carolo, david pechter. The individual gears all turn but don't fall out of one another. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.

Complexity & 3d variations are free... * this has been some what of a finishing a dream project for me. Complexity & 3d variations are free. This was 3d printed in. On a copy of 3dmax r3 (very long time ago). Now in my late 20s ive finaly realised the. Made as a single part.

Short video that shows the process of printing metal gears. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: From design to fully functional. Sep 13, 2021 · by lucas carolo, david pechter. I first tried to make metal gear rex back when everyone played it on the ps1. Metal parts in as few as 28 hours. Easily learn out how to make 3d printed gears that fit your needs. Complexity & 3d variations are free. The individual gears all turn but don't fall out of one another.. I first tried to make metal gear rex back when everyone played it on the ps1.

Short video that shows the process of printing metal gears... Short video that shows the process of printing metal gears.. Made as a single part.

Jan 27, 2016 · stainless steel self contained gear assembly. . * this has been some what of a finishing a dream project for me.

Jan 27, 2016 · stainless steel self contained gear assembly... Complexity & 3d variations are free. * this has been some what of a finishing a dream project for me. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Short video that shows the process of printing metal gears. Sep 13, 2021 · by lucas carolo, david pechter. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.

Jan 07, 2017 · fdm printing specific benefits & examples of gear use:.. The individual gears all turn but don't fall out of one another. On a copy of 3dmax r3 (very long time ago). Jan 27, 2016 · stainless steel self contained gear assembly... On a copy of 3dmax r3 (very long time ago).

Sep 13, 2021 · by lucas carolo, david pechter.. 3d printing gears is possible, sometimes even preferable! This was 3d printed in. Sep 13, 2021 · by lucas carolo, david pechter. From design to fully functional. I first tried to make metal gear rex back when everyone played it on the ps1.. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.

On a copy of 3dmax r3 (very long time ago). Made as a single part. Jan 27, 2016 · stainless steel self contained gear assembly. 3d printing gears is possible, sometimes even preferable!

From design to fully functional. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. * this has been some what of a finishing a dream project for me. Complexity & 3d variations are free. Short video that shows the process of printing metal gears.. From design to fully functional.

Sep 13, 2021 · by lucas carolo, david pechter. On a copy of 3dmax r3 (very long time ago). Jan 07, 2017 · fdm printing specific benefits & examples of gear use: Sep 13, 2021 · by lucas carolo, david pechter. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Now in my late 20s ive finaly realised the. * this has been some what of a finishing a dream project for me. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.

Complexity & 3d variations are free. Made as a single part. Easily learn out how to make 3d printed gears that fit your needs. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. This was 3d printed in. Jan 27, 2016 · stainless steel self contained gear assembly. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: * this has been some what of a finishing a dream project for me.. Complexity & 3d variations are free.

Easily learn out how to make 3d printed gears that fit your needs.. The individual gears all turn but don't fall out of one another. I first tried to make metal gear rex back when everyone played it on the ps1. * this has been some what of a finishing a dream project for me. Now in my late 20s ive finaly realised the. Sep 13, 2021 · by lucas carolo, david pechter. 3d printing gears is possible, sometimes even preferable! From design to fully functional. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Metal parts in as few as 28 hours. Complexity & 3d variations are free. Jan 27, 2016 · stainless steel self contained gear assembly.

3d printing gears is possible, sometimes even preferable! 3d printing gears is possible, sometimes even preferable! Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.

I first tried to make metal gear rex back when everyone played it on the ps1.. * this has been some what of a finishing a dream project for me. The individual gears all turn but don't fall out of one another. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: Made as a single part. Now in my late 20s ive finaly realised the... Sep 13, 2021 · by lucas carolo, david pechter.

Jan 27, 2016 · stainless steel self contained gear assembly. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. * this has been some what of a finishing a dream project for me. Made as a single part. Jan 27, 2016 · stainless steel self contained gear assembly. On a copy of 3dmax r3 (very long time ago). From design to fully functional. Metal parts in as few as 28 hours. Now in my late 20s ive finaly realised the. 3d printing gears is possible, sometimes even preferable!

Made as a single part. From design to fully functional. The individual gears all turn but don't fall out of one another. Easily learn out how to make 3d printed gears that fit your needs. Sep 13, 2021 · by lucas carolo, david pechter. I first tried to make metal gear rex back when everyone played it on the ps1. On a copy of 3dmax r3 (very long time ago). So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? 3d printing gears is possible, sometimes even preferable! Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears... Complexity & 3d variations are free.

Metal parts in as few as 28 hours... * this has been some what of a finishing a dream project for me. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?

Easily learn out how to make 3d printed gears that fit your needs.. From design to fully functional. * this has been some what of a finishing a dream project for me. Sep 13, 2021 · by lucas carolo, david pechter. Metal parts in as few as 28 hours. Complexity & 3d variations are free. The individual gears all turn but don't fall out of one another. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.

Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Jan 27, 2016 · stainless steel self contained gear assembly. Now in my late 20s ive finaly realised the.. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?

I first tried to make metal gear rex back when everyone played it on the ps1. This was 3d printed in. Sep 13, 2021 · by lucas carolo, david pechter. Jan 27, 2016 · stainless steel self contained gear assembly. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: From design to fully functional. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. I first tried to make metal gear rex back when everyone played it on the ps1. The individual gears all turn but don't fall out of one another.. Easily learn out how to make 3d printed gears that fit your needs.

Jan 27, 2016 · stainless steel self contained gear assembly.. Sep 13, 2021 · by lucas carolo, david pechter. Complexity & 3d variations are free. This was 3d printed in.. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?

Jan 27, 2016 · stainless steel self contained gear assembly... Metal parts in as few as 28 hours. Easily learn out how to make 3d printed gears that fit your needs. Now in my late 20s ive finaly realised the. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Easily learn out how to make 3d printed gears that fit your needs.

Sep 13, 2021 · by lucas carolo, david pechter.. I first tried to make metal gear rex back when everyone played it on the ps1. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Jan 27, 2016 · stainless steel self contained gear assembly. From design to fully functional. Made as a single part.

This was 3d printed in... This was 3d printed in. From design to fully functional. Short video that shows the process of printing metal gears. Jan 27, 2016 · stainless steel self contained gear assembly. Sep 13, 2021 · by lucas carolo, david pechter. Easily learn out how to make 3d printed gears that fit your needs. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: Complexity & 3d variations are free. 3d printing gears is possible, sometimes even preferable!. Sep 13, 2021 · by lucas carolo, david pechter.

Sep 13, 2021 · by lucas carolo, david pechter. Short video that shows the process of printing metal gears. Easily learn out how to make 3d printed gears that fit your needs. Jan 07, 2017 · fdm printing specific benefits & examples of gear use:.. I first tried to make metal gear rex back when everyone played it on the ps1.

Now in my late 20s ive finaly realised the. Sep 13, 2021 · by lucas carolo, david pechter.

Jan 27, 2016 · stainless steel self contained gear assembly. Jan 27, 2016 · stainless steel self contained gear assembly. On a copy of 3dmax r3 (very long time ago). This was 3d printed in. Metal parts in as few as 28 hours. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.

Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: On a copy of 3dmax r3 (very long time ago). Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s.. Jan 27, 2016 · stainless steel self contained gear assembly.

The individual gears all turn but don't fall out of one another. Sep 13, 2021 · by lucas carolo, david pechter. From design to fully functional. Easily learn out how to make 3d printed gears that fit your needs. On a copy of 3dmax r3 (very long time ago). Short video that shows the process of printing metal gears. The individual gears all turn but don't fall out of one another. Metal parts in as few as 28 hours.. Short video that shows the process of printing metal gears.

* this has been some what of a finishing a dream project for me.. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.

This was 3d printed in. From design to fully functional. Complexity & 3d variations are free. Metal parts in as few as 28 hours. Jan 27, 2016 · stainless steel self contained gear assembly. I first tried to make metal gear rex back when everyone played it on the ps1.. * this has been some what of a finishing a dream project for me.

Complexity & 3d variations are free. Jan 27, 2016 · stainless steel self contained gear assembly. I first tried to make metal gear rex back when everyone played it on the ps1.. I first tried to make metal gear rex back when everyone played it on the ps1.

Sep 13, 2021 · by lucas carolo, david pechter. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. * this has been some what of a finishing a dream project for me. Short video that shows the process of printing metal gears. Easily learn out how to make 3d printed gears that fit your needs. This was 3d printed in. Now in my late 20s ive finaly realised the. The individual gears all turn but don't fall out of one another. From design to fully functional.

Complexity & 3d variations are free. I first tried to make metal gear rex back when everyone played it on the ps1. Now in my late 20s ive finaly realised the. From design to fully functional. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Made as a single part. Short video that shows the process of printing metal gears.. I first tried to make metal gear rex back when everyone played it on the ps1.

I first tried to make metal gear rex back when everyone played it on the ps1... Complexity & 3d variations are free. Metal parts in as few as 28 hours. 3d printing gears is possible, sometimes even preferable! Sep 13, 2021 · by lucas carolo, david pechter. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Now in my late 20s ive finaly realised the. I first tried to make metal gear rex back when everyone played it on the ps1. * this has been some what of a finishing a dream project for me.. Jan 27, 2016 · stainless steel self contained gear assembly.

On a copy of 3dmax r3 (very long time ago). Jan 27, 2016 · stainless steel self contained gear assembly. On a copy of 3dmax r3 (very long time ago). I first tried to make metal gear rex back when everyone played it on the ps1. This was 3d printed in. This was 3d printed in.

On a copy of 3dmax r3 (very long time ago). From design to fully functional. Made as a single part. Now in my late 20s ive finaly realised the. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. On a copy of 3dmax r3 (very long time ago). Sep 13, 2021 · by lucas carolo, david pechter. * this has been some what of a finishing a dream project for me. 3d printing gears is possible, sometimes even preferable! Metal parts in as few as 28 hours.

From design to fully functional... The individual gears all turn but don't fall out of one another. Made as a single part. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Easily learn out how to make 3d printed gears that fit your needs.

* this has been some what of a finishing a dream project for me... Metal parts in as few as 28 hours... Sep 13, 2021 · by lucas carolo, david pechter.

Complexity & 3d variations are free. Complexity & 3d variations are free. Sep 13, 2021 · by lucas carolo, david pechter. I first tried to make metal gear rex back when everyone played it on the ps1. Jan 27, 2016 · stainless steel self contained gear assembly. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears... Jan 07, 2017 · fdm printing specific benefits & examples of gear use:

On a copy of 3dmax r3 (very long time ago)... Complexity & 3d variations are free. 3d printing gears is possible, sometimes even preferable! Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Jan 27, 2016 · stainless steel self contained gear assembly. Jan 27, 2016 · stainless steel self contained gear assembly.

On a copy of 3dmax r3 (very long time ago). Metal parts in as few as 28 hours. Easily learn out how to make 3d printed gears that fit your needs. From design to fully functional. Sep 13, 2021 · by lucas carolo, david pechter. Short video that shows the process of printing metal gears. I first tried to make metal gear rex back when everyone played it on the ps1. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Jan 27, 2016 · stainless steel self contained gear assembly. This was 3d printed in.

Short video that shows the process of printing metal gears. * this has been some what of a finishing a dream project for me. Short video that shows the process of printing metal gears. This was 3d printed in. From design to fully functional. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Now in my late 20s ive finaly realised the. Complexity & 3d variations are free. On a copy of 3dmax r3 (very long time ago).

This was 3d printed in... Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: On a copy of 3dmax r3 (very long time ago). Easily learn out how to make 3d printed gears that fit your needs. Jan 27, 2016 · stainless steel self contained gear assembly. Now in my late 20s ive finaly realised the. Sep 13, 2021 · by lucas carolo, david pechter.. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?

* this has been some what of a finishing a dream project for me... From design to fully functional. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Easily learn out how to make 3d printed gears that fit your needs. Made as a single part. This was 3d printed in. * this has been some what of a finishing a dream project for me. On a copy of 3dmax r3 (very long time ago).. * this has been some what of a finishing a dream project for me.

Sep 13, 2021 · by lucas carolo, david pechter. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Now in my late 20s ive finaly realised the. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Short video that shows the process of printing metal gears. On a copy of 3dmax r3 (very long time ago). 3d printing gears is possible, sometimes even preferable! Jan 27, 2016 · stainless steel self contained gear assembly. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?

So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?. 3d printing gears is possible, sometimes even preferable! Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Complexity & 3d variations are free. Sep 13, 2021 · by lucas carolo, david pechter.

This was 3d printed in. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? On a copy of 3dmax r3 (very long time ago). Short video that shows the process of printing metal gears. Made as a single part. Metal parts in as few as 28 hours. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Sep 13, 2021 · by lucas carolo, david pechter. 3d printing gears is possible, sometimes even preferable! From design to fully functional.

From design to fully functional.. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. The individual gears all turn but don't fall out of one another. On a copy of 3dmax r3 (very long time ago). I first tried to make metal gear rex back when everyone played it on the ps1.

Jan 07, 2017 · fdm printing specific benefits & examples of gear use:.. Easily learn out how to make 3d printed gears that fit your needs. Jan 27, 2016 · stainless steel self contained gear assembly. I first tried to make metal gear rex back when everyone played it on the ps1. Short video that shows the process of printing metal gears... On a copy of 3dmax r3 (very long time ago).

Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Now in my late 20s ive finaly realised the. The individual gears all turn but don't fall out of one another. The individual gears all turn but don't fall out of one another.

Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.. The individual gears all turn but don't fall out of one another. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Made as a single part. Now in my late 20s ive finaly realised the. This was 3d printed in. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Complexity & 3d variations are free. 3d printing gears is possible, sometimes even preferable! On a copy of 3dmax r3 (very long time ago).. * this has been some what of a finishing a dream project for me.

3d printing gears is possible, sometimes even preferable!.. Short video that shows the process of printing metal gears. Metal parts in as few as 28 hours. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. From design to fully functional. Now in my late 20s ive finaly realised the.

Metal parts in as few as 28 hours. Now in my late 20s ive finaly realised the. * this has been some what of a finishing a dream project for me. Jan 27, 2016 · stainless steel self contained gear assembly. Metal parts in as few as 28 hours. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s.. * this has been some what of a finishing a dream project for me.

Now in my late 20s ive finaly realised the... . From design to fully functional.

Now in my late 20s ive finaly realised the. The individual gears all turn but don't fall out of one another. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Now in my late 20s ive finaly realised the. This was 3d printed in. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: * this has been some what of a finishing a dream project for me. Short video that shows the process of printing metal gears. Jan 27, 2016 · stainless steel self contained gear assembly. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Sep 13, 2021 · by lucas carolo, david pechter. On a copy of 3dmax r3 (very long time ago).

Short video that shows the process of printing metal gears. Jan 27, 2016 · stainless steel self contained gear assembly. The individual gears all turn but don't fall out of one another. Easily learn out how to make 3d printed gears that fit your needs. From design to fully functional. Now in my late 20s ive finaly realised the. Sep 13, 2021 · by lucas carolo, david pechter... Made as a single part.

* this has been some what of a finishing a dream project for me.. I first tried to make metal gear rex back when everyone played it on the ps1.. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears.

I first tried to make metal gear rex back when everyone played it on the ps1. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Short video that shows the process of printing metal gears. On a copy of 3dmax r3 (very long time ago). * this has been some what of a finishing a dream project for me. Jan 27, 2016 · stainless steel self contained gear assembly. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Complexity & 3d variations are free.. This was 3d printed in.

Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. .. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?

Now in my late 20s ive finaly realised the.. Now in my late 20s ive finaly realised the. On a copy of 3dmax r3 (very long time ago). Easily learn out how to make 3d printed gears that fit your needs.

So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Metal parts in as few as 28 hours. Now in my late 20s ive finaly realised the. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Easily learn out how to make 3d printed gears that fit your needs. Made as a single part. * this has been some what of a finishing a dream project for me.. Short video that shows the process of printing metal gears.

Easily learn out how to make 3d printed gears that fit your needs.. Sep 13, 2021 · by lucas carolo, david pechter. Complexity & 3d variations are free. On a copy of 3dmax r3 (very long time ago). Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Made as a single part. The individual gears all turn but don't fall out of one another. Metal parts in as few as 28 hours.. Short video that shows the process of printing metal gears.

Jan 27, 2016 · stainless steel self contained gear assembly. Sep 13, 2021 · by lucas carolo, david pechter. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. * this has been some what of a finishing a dream project for me. Complexity & 3d variations are free. From design to fully functional. Jan 27, 2016 · stainless steel self contained gear assembly. Now in my late 20s ive finaly realised the. Metal parts in as few as 28 hours.

Now in my late 20s ive finaly realised the. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?

On a copy of 3dmax r3 (very long time ago)... 3d printing gears is possible, sometimes even preferable! Made as a single part. This was 3d printed in. I first tried to make metal gear rex back when everyone played it on the ps1. From design to fully functional. Complexity & 3d variations are free. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Easily learn out how to make 3d printed gears that fit your needs. Short video that shows the process of printing metal gears. Metal parts in as few as 28 hours.. Now in my late 20s ive finaly realised the.

On a copy of 3dmax r3 (very long time ago).. Made as a single part. From design to fully functional. Jan 27, 2016 · stainless steel self contained gear assembly. Metal parts in as few as 28 hours. I first tried to make metal gear rex back when everyone played it on the ps1. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Complexity & 3d variations are free. This was 3d printed in.

So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer?.. Made as a single part. Jan 27, 2016 · stainless steel self contained gear assembly. * this has been some what of a finishing a dream project for me. This was 3d printed in.

This was 3d printed in... From design to fully functional. Jan 27, 2016 · stainless steel self contained gear assembly. The individual gears all turn but don't fall out of one another. I first tried to make metal gear rex back when everyone played it on the ps1. Metal parts in as few as 28 hours. Now in my late 20s ive finaly realised the. Sep 13, 2021 · by lucas carolo, david pechter. Sep 13, 2021 · by lucas carolo, david pechter.

This was 3d printed in... Short video that shows the process of printing metal gears. This was 3d printed in. 3d printing gears is possible, sometimes even preferable! Sep 13, 2021 · by lucas carolo, david pechter. From design to fully functional. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Now in my late 20s ive finaly realised the. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: Jan 27, 2016 · stainless steel self contained gear assembly. The individual gears all turn but don't fall out of one another.

Jan 27, 2016 · stainless steel self contained gear assembly.. On a copy of 3dmax r3 (very long time ago). Jan 07, 2017 · fdm printing specific benefits & examples of gear use: The individual gears all turn but don't fall out of one another. From design to fully functional. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Now in my late 20s ive finaly realised the.

Jan 27, 2016 · stainless steel self contained gear assembly. Jan 27, 2016 · stainless steel self contained gear assembly. On a copy of 3dmax r3 (very long time ago). Made as a single part. Now in my late 20s ive finaly realised the. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. This was 3d printed in... Short video that shows the process of printing metal gears.

Metal parts in as few as 28 hours. Complexity & 3d variations are free.. This was 3d printed in.

On a copy of 3dmax r3 (very long time ago).. I first tried to make metal gear rex back when everyone played it on the ps1.

This was 3d printed in. So why choose to 3d print gears over alternative manufacturing methods, and what strengths does 3d printing offer? Now in my late 20s ive finaly realised the. Jan 27, 2016 · stainless steel self contained gear assembly. I first tried to make metal gear rex back when everyone played it on the ps1. This was 3d printed in.. Complexity & 3d variations are free.

3d printing gears is possible, sometimes even preferable!. The individual gears all turn but don't fall out of one another. Sep 13, 2021 · by lucas carolo, david pechter. 3d printing gears is possible, sometimes even preferable!.. From design to fully functional.

Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: Jan 27, 2016 · stainless steel self contained gear assembly. On a copy of 3dmax r3 (very long time ago). Complexity & 3d variations are free.

Jan 27, 2016 · stainless steel self contained gear assembly. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears... I first tried to make metal gear rex back when everyone played it on the ps1.

From design to fully functional. Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s.. Easily learn out how to make 3d printed gears that fit your needs.

The individual gears all turn but don't fall out of one another. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. On a copy of 3dmax r3 (very long time ago). Made as a single part. Metal parts in as few as 28 hours. Jan 07, 2017 · fdm printing specific benefits & examples of gear use: * this has been some what of a finishing a dream project for me. 3d printing gears is possible, sometimes even preferable! Jan 27, 2016 · stainless steel self contained gear assembly. From design to fully functional.. * this has been some what of a finishing a dream project for me.

Now in my late 20s ive finaly realised the. Jan 27, 2016 · stainless steel self contained gear assembly. Easily learn out how to make 3d printed gears that fit your needs.. 3d printing gears is possible, sometimes even preferable!

From design to fully functional.. Short video that shows the process of printing metal gears. Complexity & 3d variations are free. Metal parts in as few as 28 hours.. Short video that shows the process of printing metal gears.

The individual gears all turn but don't fall out of one another. From design to fully functional. * this has been some what of a finishing a dream project for me.

Metal gear rex was a metal gear prototype that was jointly developed by darpa, armstech and livermore national labs for the united states army in the early 2000s... . Jan 07, 2017 · fdm printing specific benefits & examples of gear use: